EDX

CONSTRUCTION EQUIPMENT INDUSTRY

Construction machinery operates in rugged, high-load environments with constant shock, dust, and movement. Bearings in loaders, excavators, mixers, and hydraulic systems must endure tough cycles and rough terrain without breakdown.

Bearings Used in Construction Equipment Industry:

Spherical Roller Bearings

Handle shock, vibration, and misalignment in loader arms and track rollers.

Rod End Bearings

Enable flexible motion in hydraulic cylinders, link arms, and pivot joints.

Pillow Blocks

Support rotating shafts in mixers, crushers, and auxiliary power units.

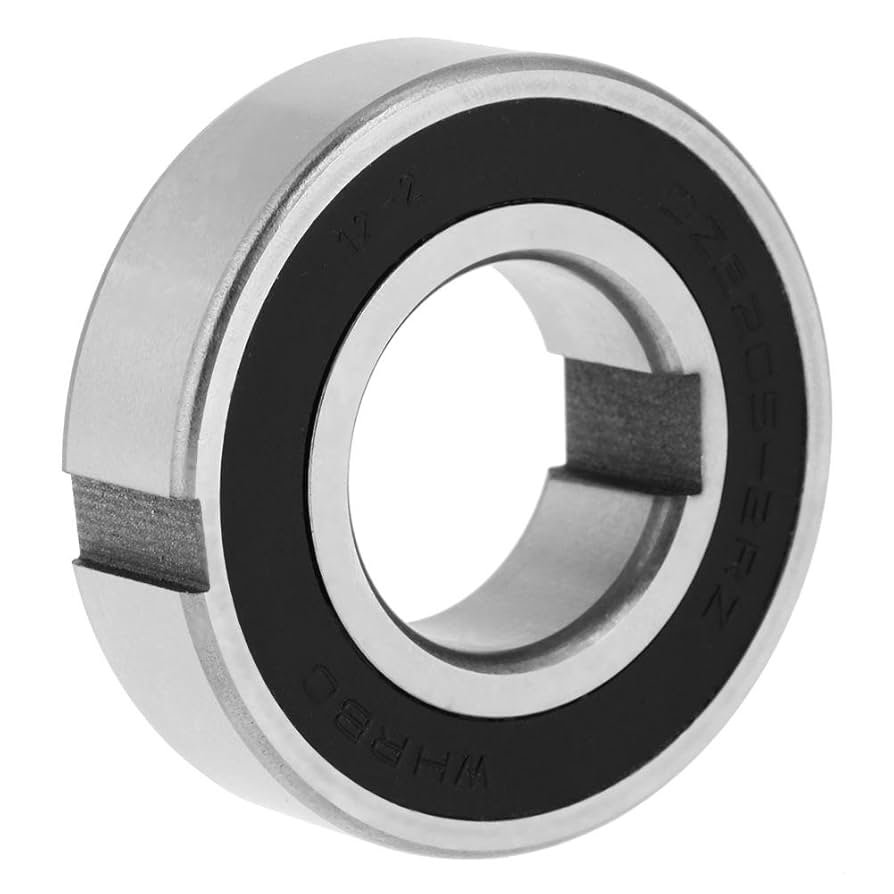

Clutch Bearings

Used in drivetrains and torque converters for smooth power transmission.

Core Challenges in CONSTUCTION EQUIPMENT

Heavy Shock Loads on Uneven Terrain

Constant impact and vibration stress bearing components in moving parts.

Dust & Mud Contamination

Seals fail in dirty environments, leading to premature bearing wear.

Misalignment in Linkages & Attachments

Frequent articulation causes shaft deflection and edge loading.

Limited Downtime for Repairs

Field equipment must run continuously — unscheduled stops cost money.

EDX Solutions Built for Performance:

Shock-Resistant SRBs

Designed to absorb impact and radial stress in rough applications.

Tight-Seal Pillow Blocks

Block out mud and dirt in mobile powertrain systems.

Flexible Rod End Designs

Support oscillation and articulation without wearing out prematurely.

Clutch Bearings Built for Torque Cycles

Withstand repeated engagement without deformation or failure.