EDX

ROLLING MILL (Steel Industry)

Operational Demands of Steel Industry

Power Transmission Core

Bearings drive rolls that compress, shape, and reduce metal thickness at high speed and load.

Operate Under Stress

Thermal shock, water contamination, and massive radial loads are routine in rolling stands.

Friction & Alignment Control

Properly aligned bearings prevent roll deflection, vibration, and edge cracking of the steel.

Bearings Define Efficiency

The right bearing ensures tight tolerances, smooth finish, and continuous mill operation.

Rolling mills are used to shape metal into various forms and dimensions. Bearings in rolling mills play a vital role in supporting the high radial and axial loads generated during the rolling process. They also ensure proper alignment and smooth operation of the rolls under heavy-duty conditions.

The Edx Advantages

High Radial Load Handling

Manages force in rolling stands and work rolls.

Withstands Water & Heat

Performs under coolant spray and thermal shock.

Split Designs Available

For faster changeover without dismantling equipment.

Low Runout Tolerance

Supports dimensional accuracy in final metal output.

Bearings integrated into Rolling Mill (Steel Industry):

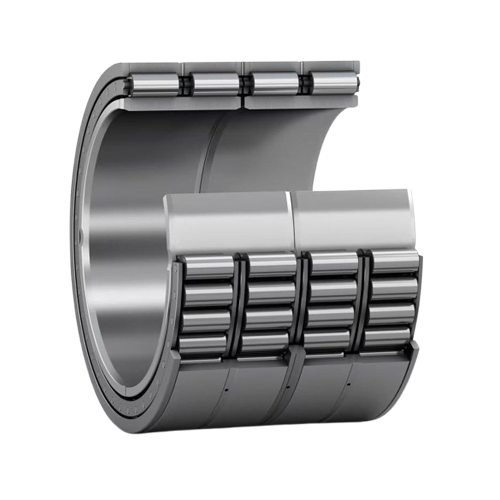

Four-Row Cylindrical Roller Bearings

Handle heavy radial loads in rolls

Spherical Roller Bearings

Tolerate misalignment during hot rolling

Split Bearings

Allow quick replacement without dismantling shafts

Standard Bearings vs. EDX Bearings Comparison Table

This table compares standard and EDX bearings in terms of performance features for rotating motor shafts.