EDX

AUTOMOTIVE INDUSTRY

From wheel hubs and transmissions to assembly lines and drive systems, bearings in the automotive industry must deliver speed, precision, and durability. They ensure smooth power transfer, low vibration, and high efficiency across every vehicle system.

Bearings Used in Automotive Industry:

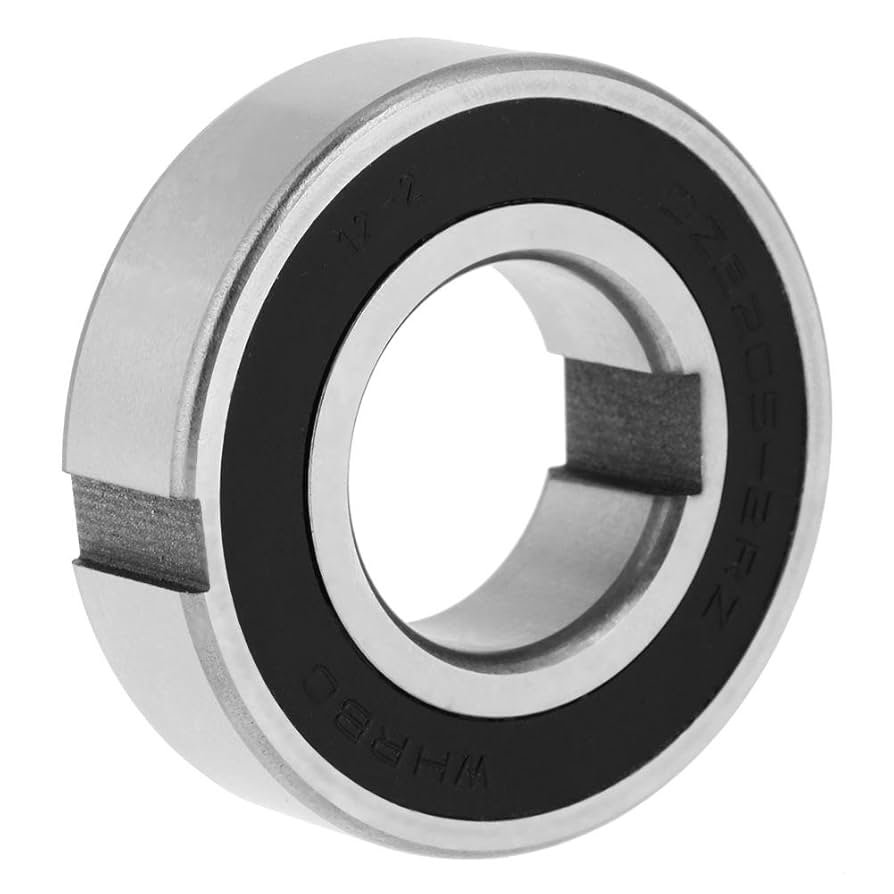

Deep Groove Ball Bearings

Enable smooth rotation in alternators, wheels, and electric motors.

Angular Contact Ball Bearings

Handle combined axial and radial loads in gearboxes and drivetrain assemblies.

Tapered Roller Bearings

Manage high-load conditions in axle hubs, differentials, and transmissions.

Clutch Bearings

Ensure reliable clutch engagement and power flow in manual vehicles.

Core Challenges in AUTOMOTIVE APPLICATIONS:

High-Speed & Continuous Operation

Automated lines and high-RPM components demand consistent, frictionless movement.

Heat Buildup in Gear & Clutch Systems

Rising temperatures can degrade lubrication and reduce bearing life.

Vibration & Load Variations

Wheel ends and engine-driven systems cause shock and misalignment.

Downtime in Assembly Lines

Any stoppage disrupts production flow and affects output targets.

EDX Solutions Built for Performance:

High-Precision Bearing Geometry

Delivers ultra-smooth, low-noise performance for fast-moving assemblies.

Heat-Resistant Greases & Materials

Ensures stability in hot transmission zones and engine bay applications.

Customized Clutch Bearing Profiles

Built for shock absorption and extended life under shifting loads.

Ready-to-Mount Units for Automation Lines

Designed for quick integration into robotic and conveyor setups.